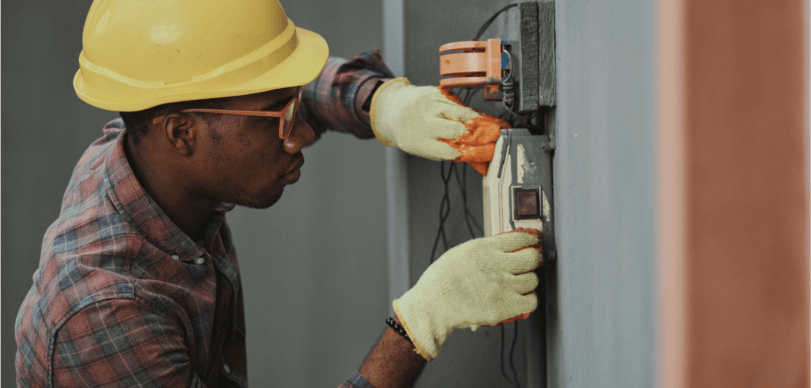

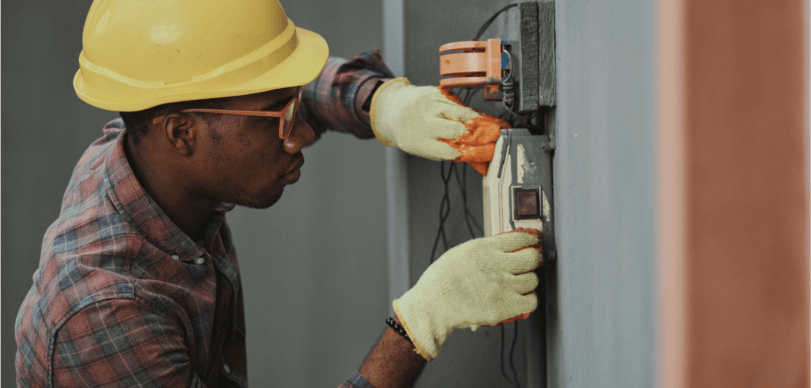

If you were electrocuted at work, it is critical you know your legal options. While you may survive the on-the-job accident, your life will probably be changed because…

If you were electrocuted at work, it is critical you know your legal options. While you may survive the on-the-job accident, your life will probably be changed because…

A crush injury is any injury or injuries that occur to any part of the body when it is when force or pressure is put on a body…

When a worker dies on the job, the employer may be held responsible for damages to surviving family members. The outcome of a potential wrongful death case will…

From online retailers to grocery store, many businesses use warehouses to ship, receive, and store materials and goods across the U.S. Factories are also necessary to produce and distribute products, providing thousands of jobs for Americans.

One of the most useful machines in a number of industries, including construction, warehousing, and manufacturing, is the forklift. When used properly, a forklift can go a long way…

Working on the railroad has always been a hazardous profession. Injury or death can occur suddenly and without warning. If you or a loved one is a railroad worker who has been injured on the job due to the negligence of the railroad company, you may be able to recover damages under the Federal Employers’ Liability Act or FELA.

In most cases, when you have been injured on the job, the only way you can recover compensation from your employer will be through the workers’ compensation system. Anyone who collects workers’ compensation in Texas for their workplace injury of illness is prohibited from filing a standard lawsuit for related damages because the law says that a workers’ compensation claim is an “exclusive remedy” for any such injury or illness.